An instrument air compressor controls the application of air for operating control valves in the oil and gas industry or any other plants.

Valves are process control equipment for industrial instruments and instrument air compressors ensure that the air passing through to power these process control equipment is of the correct pressure and temperature.

Instrumentation Air compressor

Compressed air is generally passing through after cooler,moisture trap,heater and alumina air dryer (adsortion type) so that its dew point is controlled in the range of -50 degree centigrades. I mean to say almost no moisture. This is essential for all the air actuated instruments.

Same air is distributed to instrument header and service air header.

Since the control systems are very vital for any chemical,pharmaceutical industries ,seperation of instrument air and process air is essential.

instrument air is the air system used in operating pneumatic instrument valve. the design involved more safety features.

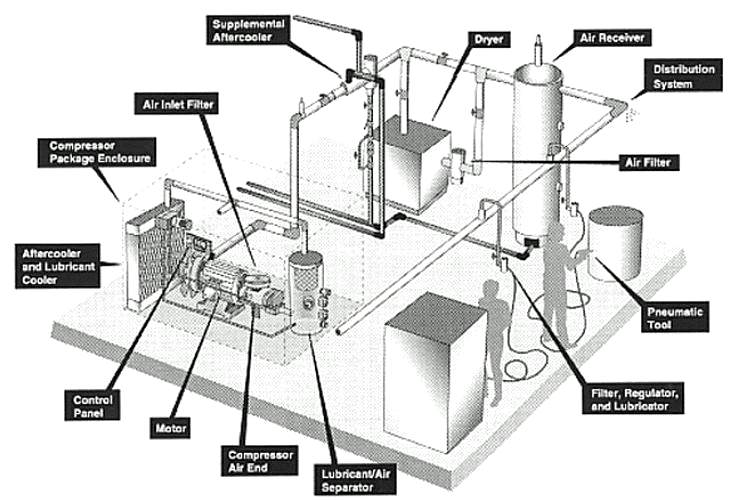

Compressor Components

The components of the compressor unit include the compressor, oil filter, drive motor, lubrication system, oil separator, after coolers, a control system and a control panel.

The Instrumentataion in a Compressor Includes :

-

Pressure Transmitters.

-

Tempreture Transmitters

-

Gas Detectors ( incase of gas leakage)

-

Flame detectors ( incase of Fire)

-

Level Switches ( to maintain the proper lubrication. If oil level or coolant level is low it will send signal to processor)

-

Flow switch ( If there is no flow of Oil or coolant due to leakage or any other blockage)

-

Flow transmitter.

-

The signals from above instruments are sent to the processor. the processor then sends controlling signals to coils which operate the actuators and valves.