An “override” control strategy involves a selection between two or more controller output signals, where only one controller at a time gets the opportunity to exert control over a process. All other “de-selected” controllers are thus overridden by the selected controller.

The general concept of override control is easily understood by appeal to a human example. Cargo truck drivers must monitor and make control decisions on a wide number of variables, including diesel engine operating parameters and road rules.

A truck driver needs to keep a close watch on the exhaust gas temperature of the truck engine: a leading indicator of impending engine damage (if exhaust temperature exceeds a pre-determined limit established by the engine manufacturer).

The same truck driver must also drive as fast as the law will allow on any given road in order to minimize shipping time and thereby maximize the amount of cargo transported over long periods of time. These two goals may become mutually exclusive when hauling heavy cargo loads up steep inclines, such as when ascending a mountain pass.

The goal of avoiding engine damage necessarily overrides the goal of maintaining legal road speed in such conditions. Imagine a diesel truck driver maintaining the legal speed limit on a highway, occasionally glancing at the EGT (Exhaust Gas Temperature) indicator in the instrument panel. Under normal operating conditions, the EGT should be well below the danger threshold for the engine.

However, after pulling a full load up a mountain pass and noticing the EGT approach the high operating limit, the truck driver makes the decision to regulate the engine’s power based on EGT rather than road speed.

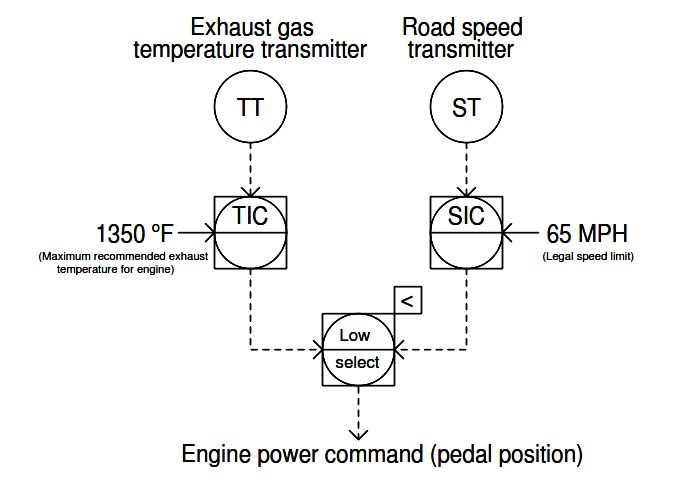

In other words, the legal speed limit is no longer the “setpoint” to control to, and EGT now is. If we were to model the truck driver’s decision-making processes in industrial instrumentation terms, it would look something like this:

Which ever control decision calls for the least engine power output, “wins the vote” to control

the engine’s power.

As is the case with limit and selector control strategies, a “select” function is used to choose one signal from multiple signals. The difference here is that the signals being selected are both controller outputs rather than transmitter (measurement) or setpoint signals. Both controllers are still active, but only one at a time will have any actual control over the process.

This model maps well to the truck driver analogy. Despite having “overridden” the goal of maintaining legal road speed in favor of maintaining a safe engine exhaust temperature, the driver is still thinking about road speed. In fact, if the driver happens to be behind schedule, you can be absolutely sure the goal of maintaining the highway speed limit has not been forgotten! In fact, the driver may become impatient as the long incline wears on, eager to make up lost time as soon as the opportunity allows.

This is a potential problem for all override control systems: making sure the de-selected controller does not “wind up” (with integral action still active) while it has no control over the process.